Repair and strengthening of stone walls. Technology for strengthening brick walls

Most often, brick walls require repair when cracks form in them.

The main reasons for the formation of cracks in the walls of a house:

- shrinkage of the building after construction for 1...1.5 years;

- deformation of foundations due to freezing and uneven thawing of groundwater;

- insufficient foundation depth;

- unequal bearing capacity of the soil within the house and, consequently, uneven settlement of its various parts;

- deformation of the beam floor;

- different loads on the soil of parts of the house, for example, an extension to the house without expansion joint;

Causes of cracks in brick walls

Rice. 1. Insufficient foundation depth.

Rice. 2. Subsidence of soil of unequal bearing capacity:

Rice. 2. Subsidence of soil of unequal bearing capacity:

1 - soil of lower bearing capacity; 2 - soil with greater bearing capacity.

Rice. 3. Formation of cracks in the walls due to deflection of the beam floor.

Rice. 3. Formation of cracks in the walls due to deflection of the beam floor.

Rice. 4. Formation of cracks in brick walls due to the lack of an expansion joint between the main building and the extension.

Rice. 4. Formation of cracks in brick walls due to the lack of an expansion joint between the main building and the extension.

Rice. 5. Formation of cracks in the walls due to the impact of increased loads on the floor structure. Cracks that are widened at the top are usually formed from the subsidence of the foundations on the side of the crack, while those that are widened at the bottom are usually formed from the subsidence of the middle part of the house.

Rice. 5. Formation of cracks in the walls due to the impact of increased loads on the floor structure. Cracks that are widened at the top are usually formed from the subsidence of the foundations on the side of the crack, while those that are widened at the bottom are usually formed from the subsidence of the middle part of the house.

Rice. 6. Analysis of cracks in stone walls using paper tapes:

Rice. 6. Analysis of cracks in stone walls using paper tapes:

1, 2 - damage to the tape with large and small displacement, respectively; 3 - tapes without offset; 4 - crack.

A common cause of cracks is shrinkage of the house. To determine the causes and record the process of formation and enlargement of cracks, paper or plaster tapes are glued to them, indicating the date of attachment. If the tape does not break within a month or more, then the shrinkage has ended and the cracks can be repaired, but if it continues to tear, then we need to look for other reasons for the formation of cracks

Methods for repairing brick walls

Rice. 7. Designs of fastenings during relocation large plots walls:

Rice. 7. Designs of fastenings during relocation large plots walls:

1 - bed; 2 - tightening; 3 - racks; 4 - lining under the racks (channel or wooden beam); 5 - metal beams;

A, B, C - zones of different loads during wall transformation.

Reinforcing the wall with metal plates

Rice. 8. Gain brick wall metal pads when tearing off a corner.

Rice. 8. Gain brick wall metal pads when tearing off a corner.

Rice. 9. Reinforcement of a brick wall with metal plates when tearing off a transverse wall.

Rice. 9. Reinforcement of a brick wall with metal plates when tearing off a transverse wall.

Rice. 10. Reinforcement of a brick wall with metal plates when the wall breaks.

Rice. 10. Reinforcement of a brick wall with metal plates when the wall breaks.

If there is a small number of destructive cracks formed after the building shrinks, metal plates are installed on the outer and inner sides of the wall and secured with bolts.

Strengthening and replacing supports

Rice. 11. Strengthening the support with brickwork:

Rice. 11. Strengthening the support with brickwork:

1 - old support; 2 - new brickwork; 3 - fittings; 4 - strip steel; 5 - concrete; 6 - steel corners.

The damaged support is reinforced with brickwork, in every 4th bedding joint of which steel reinforcement with a diameter of 3...8 mm is laid.

The support can be strengthened with steel corners bound with strip steel, followed by lining with concrete.

In some cases, it is necessary to completely change the support. To do this, all structures that transfer loads to the support are strengthened with racks with braces, and then they are dismantled. The laying of the new support is carried out using cement mortar with reinforcement with a diameter of 3...8 mm placed in the bed joints in 3...5 rows.

Rice. 12. Extension of load-bearing wall:

Rice. 12. Extension of load-bearing wall:

1 - using a multi-row horizontal fine; 2 - using small (one row) horizontal fines; 3 - using a vertical fine; 4 - extension of the wall without bandaging.

Extend load-bearing walls with and without bandaging. old load-bearing wall can be connected to the new one, if the new one is 1 floor high. To do this, nests are cut out at the end of the old wall to a height of 3...5 rows of masonry, half a brick deep. New wall laid on cement mortar.

High walls are connected to old ones without dressing, laying out the seams with strips of roofing material to fit them more tightly to each other. You can also cut a vertical groove at the end of the old wall to ensure a tight fit between the old and new walls.

New slopes for windows and doorways they are connected by bandaging more carefully (after 1...3 bricks) due to the danger of separating the junction of the new and old walls.

Strengthening the walls

Rice. 13. Strengthening the walls by increasing their cross-section:

Rice. 13. Strengthening the walls by increasing their cross-section:

1, 2 - new and old masonry, respectively.

Rice. 14. Strengthening the walls with reinforced concrete corset:

Rice. 14. Strengthening the walls with reinforced concrete corset:

1, 2 - piers reinforced with a reinforced concrete corset with an increase in the cross-section of the wall.

Strengthening the partitions between window and door openings is possible by increasing the cross-section of the partitions if the width of the opening is reduced. On one or both sides of the wall, new masonry is made using cement mortar, connecting it to the old dressing through 1...3 rows of bricks.

If it is impossible to reduce the width of the opening, then a reinforced concrete corset is installed. The surface of the corset entering the room is insulated with a layer of plaster.

When the piers are completely rebuilt, the window openings are reinforced with posts with transverse ties.

The laying of new walls is carried out using cement mortar; if necessary, it is reinforced with a wire mesh.

Sealing cracks

Rice. 15. Repairing cracks in a brick wall:

Rice. 15. Repairing cracks in a brick wall:

1 - new masonry; 2 - crack; 3-brick lintel.

Cracks can be repaired only after the walls have stopped deforming. Cracks up to 5 mm wide are filled with liquid cement mortar, having previously cleared them of dirt and washed them with water. For wider cracks, part of the masonry is dismantled and replaced with a new one, laying it out in the form of “ brick castle» from several rows of bricks on cement or mixed mortar.

The outer disassembled sections of the wall are sealed with whole, well-burnt brick in a mixed mortar in a dressing with the old masonry.

After 1 m, sections of metal or reinforced concrete beams covering the cracks are embedded into the masonry.

Replacing weak areas of masonry

With a small number of cracks, weak areas are replaced with new masonry. Sections of the wall to be replaced are strengthened metal bolts, supporting them with racks. The masonry is replaced one by one: first in the extreme areas, then in the middle and intermediate areas.

After the masonry is completed, the temporary fastenings are dismantled and the holes from the crossbars passing through the wall are sealed. The gap between the bottom of the metal beams and the new masonry is wedged with semi-dry cement mortar.

Rice. 16. Punching an opening in a load-bearing wall:

1 - stand; 2 - stand; 3 - jumper; 4 - opening in the wall; 5 - upper beam; 6 - wedges.

First, the floor is reinforced with beams, racks, supports and wedges.

The posts are nailed to the top beam with carpenter's staples. From the outside, the wall is reinforced with strips resting on stands secured with stakes driven into the ground.

Then a groove is cut out on one side and jumpers are inserted into it. The areas where the beams are supported are moistened with water, filled with cement mortar and sealed with brick or oak wedges. After the cement mortar has set, cut a groove for the remaining jumpers on the other side and install them in the same way.

After this, the masonry is finally disassembled according to the size of the opening.

Tkachev Sergey

Inspection of stone and reinforced concrete stone structures is carried out taking into account the requirements of SNiP 11-22-81 “Stone and reinforced stone structures”, as well as “Recommendations for strengthening stone structures of buildings and structures”.

Before the examination stone structures it is necessary to identify their structure by highlighting the load-bearing elements. It is especially important to take into account the actual dimensions of load-bearing elements, the design diagram, evaluate the magnitude of deformations and destruction, identify the conditions for supporting beams, slabs and other bendable elements on the masonry structure, the condition of the reinforcement (in reinforced masonry structures) and embedded parts. The size and nature of defects and the presence of typical damage (chips and cracks) directly depend on the above conditions.

For strength determination masonry uses tools and mechanical devices, as well as ultrasonic devices. Using hammers and chisels through a series of blows, you can approximately assess the qualitative condition of the stone and concrete structures. More accurate data is obtained using special hammers, i.e., mechanical devices based on the assessment of traces or results of impacts on the surface of the structure being tested. The simplest, although less accurate, tool of this type is the Fizdel hammer. A ball is pressed into the impact end of the hammer certain size. By means of an elbow strike, creating approximately the same force different people, a trace-hole remains on the surface under study. According to the size of its diameter c. Using a calibration table, the strength of the material is assessed .

More precision instrument is the Kashkarov hammer, when using which the force of the ball hitting the material under study is taken into account by the size of the mark on a special rod located behind the ball.

But the most modern and accurate mechanical devices are spring ones: the Academy device Utilities RSFSR, Central Research Institute building structures. The operating principle of these devices is based on taking into account a certain impact force caused by the release of a charged spring. A device of this type is a housing in which a spiral spring is placed, connected to a hammer rod. After pressing the trigger, the spring is released and the firing pin strikes. In the TsNIISK device, the impact force can be set to 12.5 or 50 kg/cm 2 For stone materials of varying strength.

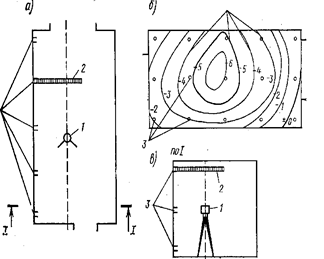

To determine the bends and deformations of vertical surfaces, their shape and the nature of deviations from verticality and plane, use a level with a special attachment that allows sighting, starting from 0.5 m instead of the minimum 3.5 m when there is no nozzle.

The relief of vertical surfaces is revealed by the method of sighting the instrument from one of its positions on the rail, applied horizontally to pre-designated points of the surface being examined. The results of measuring deformations of horizontal or vertical surfaces are plotted on diagrams on which, for clarity, lines of equal deviations from the horizontal or vertical are revealed, like horizontals planes. The cross-section is given equal to 2-5 mm depending on the degree of deviation or violation of the position or local defects of the element being examined and its overall dimensions.

However, first of all, it is necessary to find out the nature of the negative changes in the masonry and determine whether the process of crack formation has stabilized, or whether their number and opening width are increasing over time. For this purpose, they are installed in the masonry itself beacons. The beacon is a strip of plaster, glass or metal that covers both sides of the crack. Lighthouses made of plaster and glass will burst if the deformation that caused the cracks continues.

| Instruments for diagnosing the strength of a material: a - Fizdel hammer; b something Kashkarova; c - TsNIISK pistol: 1 - calibrated ball; 2 - angular scale; 3 -

calibration table; 4-replaceable rod for fixing the impact mark |

|

|

Measuring vertical surface deformations using a level with an optical attachment: a-plan; b- wall surface; c - section; 1 - level; 2 - rail; 3 - places where the slats are applied; 4 - lines of equal deviations from the plane |

|

Beacons for monitoring the condition of cracks: /-crack; 2-plaster and alabaster mortar; 3- wall material; 4- plaster beacon; 5 - glass lighthouse; 6 - metal plate; 7 - marks every 2-3 mm; 8 - nail |

By measuring the magnitude of the divergence of the halves of the beacon, the nature of the change in the crack or its stabilization is determined. Metal lighthouse attached to one side of the crack, and it can move along its other edge, on the other side of it, where the initial and subsequent positions of the end of the beacon are fixed. The simplest beacon is paper beacon, which is a strip of paper glued to a crack; with further expansion of the crack, the paper beacon breaks.

Cracks in load-bearing masonry structures correspond to the stages of crack formation (or stages of masonry operation under compression). With efforts in masonry F

, not exceeding the effort Fcrc

, in which cracks appear in the masonry, the structure has a load-bearing capacity sufficient to withstand the existing load, cracks do not form. Under loads F  Fcrc

the process of crack formation begins. Since masonry does not resist tension well, there are cracks on stretched surfaces (areas)

Fcrc

the process of crack formation begins. Since masonry does not resist tension well, there are cracks on stretched surfaces (areas)

appear much earlier than the possible destruction of the structure.

The main reasons for the formation of cracks are:

1) poor quality of masonry (poor mortar joints, non-compliance with dressings, backfilling in violation of technology, etc.);

2) insufficient strength of the brick and mortar (cracks and curvilinearity of the brick, non-compliance with the drying technology during its manufacture; high mobility of the mortar, etc.);

3) the combined use in masonry of stone materials of different strength and deformability (for example, clay bricks together with silicate bricks or cinder blocks);

4) use of stone materials for purposes other than their intended purpose (for example, sand-lime brick in conditions of high humidity);

5) low quality of work performed in winter time(use of bricks that have not been cleared of ice; use of frozen mortar, absence of anti-frost additives in the solution);

6) failure to make temperature-shrinkable seams or an unacceptably large distance between them;

7) aggressive influences external environment(acid, alkaline salt effects; alternate freezing and thawing, moistening and drying);

8) uneven settlement of the foundation in the building.

It is no coincidence that the foundation settlements are indicated last condition for the occurrence of cracks in masonry. It should be borne in mind that during the period of mass construction in masonry, mortars without antifreeze additives were used, thin, non-plastic, i.e. very cheap. All this contributed to abundant education shrinkage

cracks that must be separated from the clean surface during examination sedimentary

cracks that have a specific, easily identifiable character.

Let's consider the process of crack formation in masonry during compression

First stage- the appearance of the first hair cracks in individual stones. An effort Fcrc

at which cracks appear at this stage depends mainly on the type of mortar used in the masonry:

- in masonry with cement mortar F crc = (0.8 - 0.6) F u ; ;

- in masonry with complex mortar F crc = (0.7 - 0.5) F u ;

- in masonry with lime mortar F crc = (0.6 - 0.4) F u ,

Where F u—

destructive force.

Second stage— germination and unification of individual cracks. This stage begins and proceeds more intensely along the southern facade of the building, which experiences the greatest temperature fluctuations in the atmospheric environment. In addition, the growth of cracks is observed when external drains are improperly organized or their system is disrupted in places where the masonry periodically gets wet.

Third stage– further formation of large surfaces of destruction and exhaustion of the strength of the masonry.

|

|

|

The photograph shows a structure with an attic resting on an internal transverse wall. On the free part of the roof, a slope was created for an organized external drainage system, but the corner of the building was significantly wetted. The arrow points to a developing crack that appeared after one year of operation of the reconstructed structure. |

Defects brickwork and their reasons: a-wear from 20 to 40%; b-wear 41-60%; c- overloaded walls with wear up to 40%; d - the same, with greater wear; d - exposure of brickwork due to wear of plaster |

When analyzing the pattern of cracks, it should be remembered that the appearance of individual cracks in the dressing stones indicates overstress in the masonry. Crack development in the second stage indicates significant overstressing of the masonry and the need to unload or strengthen it.

When large destruction surfaces form, it is advisable to replace the masonry with a new one or strengthen it with a structure that can fully withstand the operational load.

During the operation of the structure, cracks may open due to an unreasonably long length of the temperature block or due to the absence of a temperature-shrinkage seam at all. During the period of reconstruction with the construction of bay windows, hanging elevators, installing additional and attic floors Cracks may appear in the masonry due to the insufficient area of support of the lintels on the wall and the low strength of the masonry, from overloading the wall and the low strength of the masonry. There are other possible causes of cracking. For example, chaotically located cracks often occur in structures that are in close proximity to the place where piles are driven, or in old buildings, the wear of the brickwork reaches 40% or more.

Strength bricks and stones must be determined in accordance with the requirements of GOST 8462-85, solution— GOST 5802-86 or SN 290-74. Density and humidity masonry determined in accordance with GOST 6427-75, 12730.2-78 by establishing the difference in the weight of the samples before and after drying. The frost resistance of stone materials and mortars, as well as their water absorption, is established according to GOST 7025-78.

Samples for testing are selected from lightly loaded structural elements, provided that the materials used in these areas are identical. Samples of bricks or stones must be intact without cracks. From stones irregular shape cut cubes with edge sizes from 40 to 200 mm or drill out the cylinders (cores) diameter from 40 to 150 mm. To test solutions, cubes with edges from 20 to 40 are made mm, composed of two mortar plates glued together gypsum mortar. Samples are tested for compression using standard laboratory equipment. Areas of brick (stone) from which samples were taken for testing must be completely restored to ensure the original structure.

Technology for restoring and strengthening brickwork

As noted above, the brick buildings of mass-produced residential buildings had high reliability and a significant margin of safety. But long term exploitation, violation technical specifications contents could cause significant damage to load-bearing brick walls. Depending on the visible damage and condition of the structures, the loads acting on them, and other factors that impede normal operation, during reconstruction measures are taken to restoration load-bearing capacity of brickwork. In addition, when increasing the number of floors of a structure or otherwise increasing the construction volume of a structure, the need arises for strengthening brick structures.

Recoverybearing capacity of masonry comes down to sealing and localizing cracks. Naturally, this problem must be solved after identifying and eliminating reasons that caused cracking:

1) eliminate or stabilize uneven foundation settlements by strengthening foundations or foundations;

2) change the conditions for transferring the load to the cracked pier in order to redistribute the load over a larger area;

3) redistribute the loads to other (or even additional) structures in case of insufficient strength of the masonry itself.

It should be noted that sealing cracks should also accompany measures to strengthening brick structures, which are necessary when loads increase and it is impossible to redistribute them to other elements of the structure.

Technologically, sealing cracks in brick walls can be done using one of the following methods or a combination of them.

Injection of cracks - injection of solutions of liquid cement or polymer-cement mortar, bitumen, resin into cracks in damaged masonry. This method of restoring the load-bearing capacity of masonry is used depending on the type of structure, the nature of its further use, the available injection capabilities, and most importantly, if the crack is local and has a small opening. It can be done using various materials. Depending on their type they distinguish silicization, bituminization, smolization And cementation. Injection allows not only to monolith the masonry, but also to restore and, in some cases, increase its load-bearing capacity, which occurs without increasing the transverse dimensions of the structure.

The most widely used are cement and polymer-cement mortars. To ensure injection efficiency, Portland cement grade of at least 400 with a grinding fineness of at least 2400 is used. cm 2 /g, with a cement paste density of 22 - 25%, as well as Portland slag cement grade 400 with low viscosity in liquefied solutions. Sand for the solution is used fine with a fineness modulus of 1.0 - 1.5 or finely ground with a grinding fineness of 2000-2200 cm 2 /g. To increase the plasticity of the composition, plasticizing additives in the form of sodium nitrite (5% by weight of cement), polyvinyl acetate PVA emulsion with a polymer cement ratio P/C = 0.6 or naphthalene-formaldehyde additive in the amount of 0.1% by weight of cement are added to the solution. .

Quite stringent requirements are imposed on injection solutions: low water separation, required viscosity, required compressive and adhesive strength, low shrinkage, high frost resistance.

At small cracks in a clutch (up to 1, 5 mm) use polymer solutions based on epoxy resin(epoxy ED-20

(or ED-16) - 100 wt.h.; modifier MGF-9 — 30 wt.h.; hardener PEPA – 15 parts by weight; finely ground sand - 50 wt.h), as well as cement-sand mortars with the addition of finely ground sand (cement - 1 parts by weight; superplasticizer naphthalene-formaldehyde – 0.1 parts by weight; sand - 0.25 parts by weight; water-cement ratio – 0.6).

At more significant opening of cracks use cement-polymer solutions of composition 1:0.15:0.3 (cement; PVA polymer; sand) or 1:0.05:0.3 (cement: plasticizer sodium nitrite: sand), W/C = 0.6 , sand fineness modulus M k =1. The solution is injected under pressure up to 0.6 MPa. The density of crack filling is determined 28 days after injection.

The solution is injected through injectors with a diameter of 20-25 mm. They are installed in special drilled holes after 0.8-1.5 meters along the length of the crack. The diameter of the holes should ensure installation of the injector tube on the cement mortar. Hole depth – no more 100 mm, the injector tube is fixed in the hole with caulked tow.

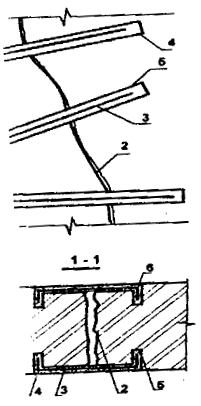

Injection of cracks up to 10 mm wide cement-sand mortar:

Injection of cracks up to 10 mm wide cement-sand mortar:

1- masonry; 2- crack; 3- holes for injectors every 800-1500 mm; 4- steel injector tube; 5- tow, caulked with glue; 6- solution supply

Installation of reinforcing steel brackets

used in methods for restoring the bearing capacity of masonry when cracks open more 10 mm. To do this, a recess is made in the masonry using a milling cutter to the size of the bracket. The bracket is secured with bolts along the edges, the crack itself is usually injected with cement-sand mortar and caulked with a rigid mortar.

Installation of brackets made of reinforcing steel: 1-reinforced wall; 2-crack in the wall, injected with cement-sand mortar after installing brackets; 3-brackets made of reinforcing steel; 4-groove in the masonry, selected with a milling cutter; 5-recesses at the ends of the groove, made with a drill; 6-filling grooves and recesses with cement-sand mortar

At significant damage masonry a network of cracks staples perform double-sided, in this case the masonry experiences double-sided compression. Development of numerous end-to-end cracks can be stopped by using a staple instead strip steel plates , which are installed in increments of 1.5-2 wall thicknesses.

|

|

|

|

|

|

|

|

|

Double-sided brackets made of reinforcing steel with bolts: 1- masonry; 2- through crack; 3- plates made of strip steel; 4- coupling bolts; 5 holes in the wall |

||

The damage can be so significant that in some cases partial dismantling and re-building of the destroyed brickwork is required. Typically this is done with the device inserts of brick locks equipped with an anchor .

|

Wide, more 10 mm, crack ( 1 ) intercepted by a one- or two-sided overlay ( 2) , no longer made of strip steel, but of rolled metal, which is attached to the wall with anchor bolts. In this case, the overlay is called anchor. Along the entire length of the development of the crack, the damaged brick is removed to a thickness of two bricks and replaced with reinforced masonry on cement-sand mortar, called brick castle (3-4

).

|

|

Partial or complete filling of openings with masonry: 1- reinforced partition; 2- window openings; 3- reinforced brickwork of grade M75-100 on mortar M50-75; 4- seam, wedged with a metal plate and caulked with cement-sand mortar |

|

Scheme for unloading brick walls: 1 - jumpers, 2 - boards 50-60 mm; 3- racks with a diameter of more than 20 cm; 4 - wooden wedges; 5- temporary fastening of racks |

Increased bearing capacity and stability of piers can be ensured increasing cross-sectional area

, device of various clips

or metal frame.

Increasing cross-sectional area The wall is reached by increasing its width. In this case, new sections of masonry are laid out on both sides of the wall, which is securely tied to the old one, and, if necessary, reinforced. Damaged load-bearing walls are unloaded, the cross-sectional area of the walls increases, and the area of window openings decreases accordingly, therefore window blocks subject to replacement.

When resting on a reinforced pier of a truss structure or when the wall deviates from the vertical by more than 1/3 of the brick thickness, the pier is first unloaded by placing temporary wooden or metal poles on gypsum solutions.

Main ways reinforcement of brickwork,

are well-tested methods of device clips, build-ups

or shirts,

divided into reinforced concrete

And mortar

. When amplified reinforced concrete frames, jackets And build-ups class B10 concrete and class A1 reinforcement are used, the transverse reinforcement spacing is taken to be no more than 15 cm. The thickness of the holder is determined by calculation and varies from 4

before 12 cm.

Mortar clips, shirts And building up, also called plastering, differ from reinforced concrete because they use grade 75-100 cement mortar, which protects the reinforcement reinforcement.

Construction of a reinforced concrete frame effective in case of surface destruction of the material of piers and pillars to a small depth or when deep cracks occur, when widening of the piers is possible. In the first case, the destroyed sections of the pier are cleared to a depth of at least the thickness of the reinforced concrete casing, and the section of the pier does not change as a result of its construction. In the second case, the cross-section of the pier is increased due to the installation of a reinforced concrete cage.

The technological process of installing a reinforced concrete frame of piers consists of removing window fillings, clearing damaged areas or cutting down the pier to the required depth, removing window quarters, installing reinforcement, installing formwork, concreting, maintaining concrete, removing formwork and dismantling scaffolding. The working reinforcement of a reinforced concrete cage can be pre-stressed by heating up to 100-150° C (for example, heating by electric current).

|

Construction of reinforced concrete frames: a-without increasing the cross-section of the pier; b-with magnification sections pier |

|

|

|

Construction of a pre-stressed plaster frame: 1-reinforced wall; 2-metal plates with holes for cords; 3-strand-connections; 4 holes in the wall for cords; 5-reinforcing bars welded to the plates and tightened in pairs; 6- plaster made of cement-sand mortar; 7-reinforcement mesh tied to bars |

Instead of reinforcement cages when reinforcing, it is possible to use wire mesh with a diameter 4-6 mm with cell 150x150 mm. In both cases of reinforcement, both meshes and frames are attached to the reinforced surface with pins (anchors).

For large areas, additional tie clamps are installed in steps of no more than 1m with average length 75 cm.

The formwork of the reinforced concrete frame is built up from the bottom up during the concreting process. To construct reinforced concrete frames, the shotcrete method is used, in which formwork is not required. In this case, it is applied under pressure to the reinforced surface of the wall. concrete mixture using a cement gun. The advantage of this method of constructing a reinforced concrete frame is the mechanization of the concreting process. The reinforced concrete cage increases the load-bearing capacity of the element enclosed in it by 2 times

|

|

|

Reinforced concrete frame clamps: 1- reinforced wall surface; 2- fittings with a diameter of 10 mm; 3- tie clamps with a diameter of 10 mm; 4 - holes in the masonry; 5 - concrete frame; 6- reinforcement cages |

|

|

|

| Construction of a plaster or reinforced concrete jacket: 1-reinforced wall; 2-armholes; 3-plaster jacket 30-40 mm or reinforced concrete jacket 60-100 mm thick; 4-reinforcement with a diameter of 10 mm; 5-reinforcement with a diameter of 12 mm; 6-metal pins | Construction of a reinforced concrete core: 1-reinforced wall; 2-openings; 3-post (core) made of reinforced concrete;

4-niche cut into the pier; 5-reinforcement frame; 6-concrete |

Mortar shirts and extensions

differ from clips only in one design feature - they are made one-sided. The shirt can be made not over the entire width of the wall - in the form core.

Sometimes steel clips for reinforcing brickwork on constantly used buildings are left without protective coating mortar or concrete, arranging metal carcass

gain.

|

|

| Reinforcement of piers with a metal frame: a- narrow pier; b- wide pier; 1-brick element; 2-steel corners; 3-bar; 4-cross link |

|

|

Construction of overhead belts from corners: 1-reinforced partition; 2-corners of overhead belts; 3-cross bars; 4-pin bolts; 5-plaster with cement-sand mortar on a metal mesh |

The construction of a metal frame of piers is less labor-intensive and material-intensive than the construction of a reinforced concrete frame, and is widely used.

Preparation for the installation of metal frames of piers consists of unloading the piers, removing the filling of window openings and cutting down the quarters. With this method, corner steel racks are installed at the corners of the piers to their full height and tightly adjusted to the piers, which are connected after 30-50 cm in height with strip steel, butt-welded to the corner flanges. Then the wall is covered with wire metal mesh and plastered.

The metal frame can be placed on the wall or embedded flush into it. In the second case, before installing the frame, the corners of the walls are cut off and horizontal grooves are punched in the places where the metal connecting strips are installed.

After installing the frame, the gaps between metal elements and the wall is carefully caulked with mortar. If the lintels resting on the pier are also destroyed, it becomes more effective to strengthen the pier by adding racks from the corners. In this case, the racks are made slightly longer than the distance between the lintel and the floor. At the top they are attached to the exposed reinforcement of the jumpers, and at the bottom to an overhead belt made of channel, mounted on the body of the object being reconstructed. The racks are straightened in pairs with clamps, thus creating pre-stress. Straightening, breaks, cuts in the flanges of the corners are welded.

Gain corners buildings are also advisable to produce using channel overlays length 1.5-3 m. Overlays can be placed both on the outside and on the outside inner surface walls. They are connected to the brickwork using tie bolts installed in pre-drilled holes. The coupling bolts are located along the height of the reinforced part of the masonry through 0.8-1.5 m.

|

|

Connecting the racks from the corners: 1-reinforced partition; 2-openings; 3-racks of unequal corners, curved to the side; 4-break lines; 5-fold part; 6-exposed reinforcement; 7-welding; 8-solution |

|

|

|

If local deformations occur and to prevent further crack opening, it is carried out by strengthening interface zones longitudinal and transverse walls of the building unloading beams . Unloading beams are installed in previously punched grooves on one or both sides of the wall at the level of the top of the foundation or lintels of the first floor.

Double-sided beams through 2-2.5 m connected by bolts with diameter l6-20 mm, passed through previously drilled holes in the beams and wall. One-sided beams are installed on anchor bolts, the smooth ends of which are secured in the wall by installing them with cement mortar into previously drilled sockets. Beam connections with bolts are secured with nuts. Anchor bolt spacing 2-2.5 m.

The gaps between the flanges of the beams and the brickwork are carefully caulked with cement mortar of a composition of 1:3. For the manufacture of unloading beams, a channel or I-beam No. 20-27 is used. In places where walls break, cracks are installed on each floor using clamps made from scraps of rolled stock with a length of at least 2 m. Before installing the bracket-screed, a groove is cut out in the wall so that the screed is installed flush with the surface of the brick wall. Holes for bolts are drilled in the wall and in the screed according to the markings. 20- 22 mm, with the help of which the bracket-screed is attached to the wall. The distance from the crack to the bolt installation site must be at least 70 cm. Before installation, the tie-brace is wrapped wire mesh or wire 1-2 mm. After installing the structure, the crack and the fine are carefully sealed with a brand solution M100.

|

|

|

Installation of metal plates (frame) when reinforcing a building: 1-deformed building; 2-cracks in the walls of the building; 3-linings made of channels or metal plates; 5-pin bolts; 6-fine for installing plates, sealed with mortar; 7-holes in the walls for bolts, after installing the bolts they are caulked with mortar |

Typically, development cracks related to uneven settlement of foundations, requires additional measures not only to increase the load-bearing capacity of the masonry, but the rigidity of the entire structure as a whole. Gross violation of masonry technology, unacceptable operating conditions of the structure, as in the case of uneven settlement of foundations, cause not only the development of cracks at window and door openings, but also violations of the verticality of enclosing structures.

In places tearing off external walls from internal ones to restore the rigidity of the building, connections are made from metal frames or reinforced concrete dowels. In this case they say that the building reinforced.

However, most often, after eliminating the causes of uneven settlement of the foundation, the building needs tightening the body generally. Perhaps the only way to do this is to creation of tension belts .

|

|

|

|

Construction of external stressed belts: 1-deformed building; 2-steel rods; 3-roll profile from angle No. 150; 4 turnbuckles; 5-weld seam; 6- cracks in the walls of the building; 7-hole in the wall filled with cement-sand mortar

It should be emphasized here that the most common mistake in strengthening the body brick buildings with a hard design diagram is the creation vertical stiffening discs(laying in or reducing the area of window openings, installing vertical metal frames, etc.), while the most important thing here is horizontal stiffening disc. The tension belt, also called "bandage", is made from reinforcing bars with a diameter 20-40 mm connected by turnbuckles.

In rare cases, rolled steel is used instead of reinforcement. The result is a reinforcing element that absorbs both tensile and compressive forces, called spacer connection. Spacer ties are installed at the covering level and at the level interfloor ceilings, they can be located both from the outside and from the inside structures.

|

|

|

|

| Construction of internal stress zones: 1-deformation building; 2-steel rods with nuts; 3-metal plates; 4 turnbuckles; 5-holes in the walls, which are sealed with mortar after packing the strands; 6-cracks in the walls of the building | |

Strengthening interfloor ceilings residential buildings of series 1-447 is determined by the presence of short cracks and fragmentation of brick stone in the places where the floor slabs support. The main cause of destruction is usually an insufficient support area for the floor slab or the absence of a distribution pad.

Most effective technique amplification is a mounting technology steel rods And spacer ties under the floor slab, since, as already noted, the creation of a horizontal rigidity disk in buildings of this type is of paramount importance. However, this is a very expensive and time-consuming method; it is only possible with complete reconstruction with resettlement of residents. Therefore, they try to fulfill local strengthening damaged structures.

Local reinforcement, depending on the type of floor slabs, during partial or phased reconstruction is carried out by:

—increasing the support area of the beam using metal or reinforced concrete racks, the force from which is transmitted outside the destruction zone;

-increasing the support area of the slab by means of a belt fixed in the zone of destruction of the masonry;

- devices under the end of the floor slabs of reinforced concrete pads.

Calculation of brick elements reinforced with reinforcement and clips

Longitudinal reinforcement , designed to absorb tensile forces in eccentrically compressed elements (at large eccentricities), in bending and tensile elements, in reinforcing brickwork during reconstruction, is quite rare, so it is not considered in this section. However, with the growth seismic dangers of some areas central Russia due to underground workings and other anthropogenic factors, as well as when laying railways and highways near residential areas, longitudinal reinforcement is used when lining thin (up to 51 cm) brick walls of reconstructed buildings.

Mesh reinforcement masonry sections significantly increases the load-bearing capacity of reinforced elements of stone structures (pillars, piers and individual sections of walls). The effectiveness of mesh reinforcement during reinforcement is determined by the fact that reinforcing meshes laid in the horizontal seams of masonry sections prevent its transverse expansion during longitudinal deformations caused by acting loads, and thereby increase the load-bearing capacity of the masonry body as a whole.

Mesh reinforcement is used to strengthen masonry made of all types of bricks, as well as ceramic stones with slot-like vertical voids with a row height of no more than 150 mm. Reinforcement of concrete and masonry with mesh reinforcement natural stones with a row height of more than 150 mm little effective.

For masonry with mesh reinforcement, mortars of grade 50 and higher are used. Mesh reinforcement is used only for flexibility or, as well as for eccentricities located within the core of the section (for rectangular sections e 0<0,33 y). При больших значениях гибкостей и эксцентрицитетов сетчатое армирование не повышает прочности кладки.

For example, it is required to determine the cross-section of longitudinal reinforcement for a brick pillar 51 x 64 cm, height 4.5 m. The pillar is made of ordinary clay bricks of plastic pressing brand 100

on brand solution 50

. In the middle section of the column, the reduced calculated longitudinal force acts N p=25 t, applied with eccentricity e o =

25 cm towards the side of the section having size 64 cm.

We reinforce the column with longitudinal reinforcement located in the tension zone outside the masonry. We reinforce the compressed zone of the cross section of the column structurally, since when the reinforcement is located externally, frequent installation of clamps will be required to prevent buckling of the compressed reinforcement, which will require additional waste of steel. The installation of structural reinforcement in the compressed area is mandatory, as it is necessary for attaching the clamps.

Cross-sectional area of the pillar F=51 x 64 = 3260 cm 2. R=l5 kgf/cm 2(at F > 0.3 m 2). Design resistance of longitudinal reinforcement made of steel class A-1R a =l900 kgf/cm2.

We take stretched reinforcement from four rods with a diameter of 10 mm F a =3.14 cm 2.

Determine the height of the compressed section zone X at h 0 =65 cm, e=58 mass media b=51 cm:

1.25-15-51 x (58-65+)-1900 -3.14-58 = 0,

and from the received quadratic equation define x= 35 cm<

0.55h o =36 cm.

Since the condition is satisfied, the load-bearing capacity of the section is determined by at =1000:

pr = = =7

hence = 0.94.

Section bearing capacity

0.94(1.25 x 15 x 51 x 35-1900 x 3.14) =25.6 t >N p =25 t.

Thus, with the adopted reinforcement cross-section, the bearing capacity of the column is sufficient.

Complex designs are made of masonry reinforced with reinforced concrete working together with the masonry. It is recommended to place reinforced concrete on the outside of the masonry , which allows you to check the quality of the laid concrete, the grade of which should be taken to be 100-150.

Complex structures are used in the same cases as masonry with longitudinal reinforcement. In addition, it is advisable to use them, just like mesh reinforcement, to strengthen heavily loaded elements under axial or eccentric compression with small eccentricities. The use of complex structures in this case makes it possible to sharply reduce the cross-sectional dimensions of walls and pillars.

Elements reinforced with clips are used to strengthen pillars and piers having a square or rectangular cross-section with an aspect ratio of no more than 2.5. The need for such reinforcement arises, for example, when adding to existing buildings. Sometimes it is necessary to strengthen masonry that has cracks or other defects (insufficient strength of the materials used, poor quality of masonry, physical wear, etc.)

Clips, as well as mesh reinforcement, reduce transverse deformations of masonry and thereby increase its load-bearing capacity. In addition, the clip itself also absorbs part of the load.

In the previous sections, three types of clips were considered: steel, reinforced concrete and reinforced plaster .

Calculation of elements made of brickwork, reinforced with clips, under central and eccentric compression at small eccentricities (not beyond the core of the section) is carried out according to the formulas:

with steel frame

N n [(m to R + ) F+R a F a ];

with reinforced concrete frame

N n [(m to R + ) F+m b R pr F b +R a F a ];

with reinforced plaster casing

N (m R + ) F.

The values of the coefficients are accepted:

at central compression=1 and =1;

with eccentric compression (by analogy with eccentrically compressed elements with mesh reinforcement)

1 — , where

N p - reduced longitudinal force; F- masonry cross-sectional area;

F a- cross-sectional area of the longitudinal corners of the steel cage installed on the mortar, or the longitudinal reinforcement of the reinforced concrete cage;

f b - cross-sectional area of the concrete cage enclosed between the clamps and the masonry (without taking into account the protective layer);

R a - design resistance of the transverse or longitudinal reinforcement of the cage;

- buckling coefficient, when determining the value A accepted as for unreinforced masonry;

t to - masonry operating conditions coefficient; for masonry without damage t to=1; for masonry with cracks t to =0,7;

t b - concrete operating conditions coefficient; when transferring the load to the holder from both sides (bottom and top) t b

=1; when transferring the load to the holder from one side (bottom or top) t b=0.7; without direct load transfer to the holder t b =0,35.

- percentage of reinforcement determined by the formula

x 100,

Where f x- cross-section of the clamp or crossbar;

h And b- dimensions of the sides of the reinforced element;

s- axle distance cross bars with steel clips ( hs b, but no more than 50 cm.) or between clamps for reinforced concrete and reinforced plaster clamps (s15 cm).

For example, in the middle section of the pier measuring 51x90 cm, located on the ground floor of the building, after completion of construction of the superstructure, the calculated longitudinal force will apply N n =60 t applied with eccentricity e O = 5 cm, directed towards the inner edge of the wall. The partition is made of sand-lime brick, grade 125, with mortar, grade 25. The height of the wall (from the floor level to the bottom of the prefabricated reinforced concrete floor) is 5 m. It is necessary to check the load-bearing capacity of the wall.

Pier section F= 51 x 90 = 4590 cm 2 > 0.3 m 2.

Design resistance of masonry R = l4 kgf/cm 2. Distance from the center of gravity of the section to its edge in the direction of eccentricity

y = = 25.5 cm; = =0.2<0,33,

the eccentricity is within the core of the section. We design the wall for eccentric compression with low eccentricity. The elastic characteristics of sand-lime brick masonry on mortar grade 25 is = 750.

Reduced flexibility of the wall np == 11.3.

Buckling coefficient = 0.85.

Coefficient taking into account the influence of eccentricity = 0.83.

Let us determine the load-bearing capacity of the pier:

0.85 x 14 x 4590 x 0.83 = 45,200kgf

Since the load-bearing capacity of the wall turned out to be insufficient, we reinforce it with a frame made of steel isosceles angles measuring 60x60 mm, d=6 mm. The corners are installed on the mortar in the corners of the wall and connected to each other by strips of strip steel with a section of 5x35 mm, welded to the corners at a distance s=50 cm along the height of the wall.

Next, we determine the load-bearing capacity enhanced pier. Coefficient of masonry operating conditions t k =1. Design resistance of steel strips R a =1500 kgf/cm2. Sectional area of the plank f x= 0.5x3.5= 1.75 cm 2. Design resistance of the corners of the cage (the load is not transferred to the corners) R a =430 kgf/cm 2. Sectional area of corners F a=6.91x4=27.6 cm 2. Next, we determine the coefficients and , =0,83, =1-=0,61 and the corresponding percentage of reinforcement: =x100=0.21%

Hence the load-bearing capacity of the reinforced wall will be:

0.83.0.85[(14 +0.61хх)4590+430 x27.6]=63800kgf > N p =60000 kgf

The load-bearing capacity of the reinforced wall is sufficient.

Structural schemes for strengthening stone structures

An effective way to strengthen stone structures is to enclose the masonry in a steel or reinforced concrete frame.

The steel frame consists of vertical corners installed on the mortar at the corners of the reinforced element and clamps made of strip steel or round rods welded to the corners. The distance between the clamps should be no less than the smaller cross-sectional size and no more than 50 cm. The steel frame should be protected from corrosion by a layer of cement mortar 25-30 mm thick. To ensure reliable adhesion of the solution, the steel corners are covered with a metal mesh.

The reinforced concrete cage is made of concrete of class no lower than B12.5 with reinforcement with vertical rods and welded clamps. The distance between the clamps should be no more than 15 cm. The thickness of the clamp is determined by calculation and can be from 4 to 12 cm. Repair of damaged masonry walls, pillars, piers, foundations is carried out by the injection method, in which liquid cement or polymer is injected into the damaged masonry under pressure mortar, which helps seal cracks, pores and voids in the masonry.

Preparatory work for masonry injection includes: determining the location of wells, drilling wells and installing metal pipes in them; cleaning cracks and masonry surfaces from drilling sludge and dust; sealing all cracks by plastering with a thin layer of cement mortar. When injecting, Portland cement of a grade of at least 400 with a grinding fineness of at least 2400 cm 2 /g is used as a binder for cement and cement-polymer mortars. The solution is injected into the structure under pressure up to 0.6 MPa. Injection pipes 6-10 cm long are made from scraps of gas pipes and have a thread of 5-6 turns at one end.

Repair of stone structures can be carried out by replacing damaged masonry with new one. The method of replacing structures with new ones requires the preliminary installation of temporary fastenings for the period of work, capable of absorbing the upstream loads transmitted to them. After installing temporary fastenings, it is allowed to dismantle the old masonry and create a new one using mesh reinforcement.

Repair of brick and concrete walls (Fig. 4.1) in case of destruction of masonry due to defrosting in buildings with high humidity is carried out by applying an additional layer of insulation to the outside of the wall while simultaneously installing an air gap. Additional insulation protects the wall structure from exposure to negative temperatures, and the air gap serves to remove excess moisture from the walls.

Rice. 4.1 Installation of an additional layer of insulation on the outside of the wall

Glass or mineral wool insulation and profiled sheets (steel or asbestos-cement) are attached with supporting corners to the wall using special elements. Profiled sheets are attached to the support corners with self-tapping screws. Ventilated layers are formed by the internal cavities of profiled sheets.

If the strength of the masonry weakens before the fencing is installed on the outside, it is necessary to reinforce the masonry with gunite.

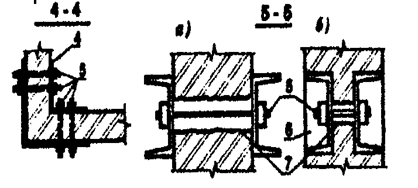

Reinforcement of pillars, piers and pilasters with clips is shown in Fig. 4.2; 4.3. The load-bearing capacity of stone and brick pillars, piers, pilasters and pylons can be significantly increased by installing steel, reinforced concrete or reinforced mortar cages that create lateral compression of the masonry. Clips are installed in cases where the load-bearing capacity of pillars, piers and pilasters is insufficient during the reconstruction and addition of buildings or in case of significant damage to the masonry (cracks, crushing, chips).

Rice. 4.2 Reinforcement of pillars (piers) with clips: a - metal; b - reinforced concrete; 1- brick pillar; 2 - steel corners; 3 - strips; 4 - concrete; 5 - longitudinal reinforcement with a diameter of 6-12 mm; 6 - clamps with a diameter of 4-10 mm; 7 - new masonry, reinforced with mesh in 3 rows; 8 - welding

Rice. 4.3 Reinforcement of pilasters with clips: a - steel; b - reinforced concrete; 1 - steel corners; 2 - connecting strips (clamps); 3 - thrust washer 10-12 mm; 4 - bolt with a diameter of 18-22 mm; 5 - caulking with cement mortar; 6 - clamp with a diameter of 18-22 mm; 7 - reinforcing mesh with a diameter of 8-12 mm; 8 - concrete; 9 - concrete crackers

The steel frame consists of vertical corners installed on the mortar at the corners of the reinforced element, and clamps (transverse strips) made of strip steel or round rods welded to the corners. The distance between the clamps should be no less than the smaller cross-sectional area of the element and no more than 55 cm. To protect against corrosion, the steel cage is plastered with M50-100 cement mortar 2-3 cm thick over a metal mesh. The cross-section of corners and clamps is determined by calculation. It is recommended to use corners with flanges measuring 50-75 mm and clamps made of strip steel with a cross-section of 40x5-60x12 mm or round steel with a diameter of 12-30 mm.

To obtain the effect of compressing the masonry, the gap between the masonry and the corners should be carefully sealed (caulked) with M50-100 cement mortar and compressed using tension clamps (Fig. 4.4). To tighten the nuts, tighten them with a torque wrench. The tension value is 30-40 kN.

Rice. 4.4 Reinforcement of stone pillars with metal tension clips: 1 - corners; 2 - corner segment; 3 - transverse rod; 4 - nut; 5 - washer; 6 - plaster layer; 7 - straight wedge; 8 - reverse wedge; 9 - stiffener; 10 - support corner

The reinforced concrete frame is made of concrete B 12.5 and higher with reinforcement with vertical rods with a diameter of 10-16 mm and clamps with a diameter of 6-10 mm. The distance between the clamps should be no more than 15 cm. The class of concrete should be greater than the grade of brick. The thickness of the frame is taken by calculation and can vary from 4 to 12 cm. Concreting is carried out in formwork.

Strengthening stone structures with reinforced mortar clips is done in the same way as with reinforced concrete clips. In this case, instead of concrete, M75-200 cement mortar is applied to the surface of the structures in layers of 2-3 cm manually, using a mortar pump or by shotcrete.

If the ratio of the width of the column or wall to the thickness is more than two, additional transverse links are installed in the middle, passed through the masonry at a distance of no more than two thicknesses and no more than 100 cm.

Damaged pilasters are reinforced with steel or reinforced concrete frames, as shown in Fig. 4.3. The clips should cover the pilaster on three sides. In this case, clamps with a diameter of 18-22 mm are passed through the wall. After installing the clamps, the clamps are tightened from the outside using nuts, under which steel thrust washers 10x10 cm, 10-12 mm thick, or channel cuttings are placed.

Before installing the frames, it is recommended to strengthen the masonry of pillars, piers and pilasters damaged by cracks by injecting cement or cement-polymer mortar.

Steel, reinforced concrete and mortar frames are calculated in accordance with the Guidelines for the Design of Stone and Reinforced Stone Structures (M.: Stroyizdat, 1984).

In case of local damage to the masonry of piers, pillars, pilasters (vertical or oblique cracks of short length, crushing and chipping of the masonry under the ends of the lintels in places where beams and trusses support), the installation of clips is not necessary. It is enough to tighten the damaged areas with single clamps (bandages) made of 6x60 (80) mm strip steel (Fig. 4.5), and inject the damaged masonry with cement mortar under pressure.

Rice. 4.5 Reinforcement of the wall with a steel clamp: 1 - clamp made of strip steel 6x60 (80) mm; 2 - jumper; 3 - sealing with M100 cement mortar; 4 - crack; 5 - pier; 6 - welding

The solidity and bearing capacity of stone structures damaged by cracks (walls, pillars, piers, vaults, etc.) can be restored by injecting (injecting) cement, cement-polymer and polymer solutions into the masonry under pressure up to 0.6 MPa using manual or mechanical pumps. The solidity and strength of the masonry increases due to the gluing effect of the mortars and their filling of voids and cracks in the masonry.

The load-bearing capacity of brickwork damaged by cracks under compression after injection with cement and cement-polymer mortar is calculated as a monolithic masonry in accordance with SNiP P-22-81 “Stone and reinforced masonry structures” multiplied by the coefficients m k: when injected with cement and cement-polymer mortars m k =1.1; the same, with polymer solutions m k =l.3; when injecting individual cracks that arose under the influence of temperature, shrinkage, and uneven settlement of foundations m k = 1.

The load-bearing capacity of masonry walls and foundations can be significantly increased by laying (new masonry) or overlaying walls on one or both sides. The walls and foundations are laid from the same materials as the main wall.

To increase the load-bearing capacity, the masonry is reinforced with meshes and frames. The thickness of the pad, determined by calculation, can vary from 12 to 38 cm or more. To ensure collaboration with the main masonry, the butt must have a constructive connection with the main masonry (banding, dowels, pins, through rods, etc.).

The concrete lining of the walls is made of heavy or light concrete B7.5-15, reinforced with mesh with a diameter of 4-12 mm (Fig. 4.6). The thickness of the concrete layers, determined by calculation, ranges from 4 to 12 cm. Concrete is laid to the height of the floor in formwork with vibration or layer-by-layer concreting using the shotcrete method.

To increase the adhesion of concrete to masonry, horizontal and vertical seams are first cleared, the surface of the masonry walls is notched and washed with water.

Reinforcing mesh is attached to steel pins with a diameter of 5-10 mm, embedded in Ml00 cement mortar into masonry joints or holes drilled with an electric drill.

For walls made of bricks and stones of regular shape, the depth of embedding the pins is 8-12 cm, the spacing of the pins along the length and height is 60-70 cm, with a staggered arrangement - 90 cm.

When laying double-sided concrete on walls and foundations made of rubble masonry, through connecting rods with a diameter of 12-20 mm are installed. The spacing of the rods for good adhesion of concrete to rubble masonry is 1 m.

The load-bearing capacity of walls and foundations reinforced with concrete is calculated as for multilayer walls with a rigid connection between layers in accordance with the Manual on the design of stone and reinforced masonry structures (M., 1987) to SNiP P-22-81.

Rice. 4.6 Reinforcement of walls with concrete: 1 - wall; 2 - floor slabs; 3 - nabetonka; 4 - pins with a diameter of 10 mm; 5 - reinforcing mesh with a diameter of 6-8 mm

Pillars and piers are repositioned in the following cases: when structures are reinforced with clips, injection, etc. economically and technically impractical (significant damage or weakening of the section, emergency condition of the masonry); during the superstructure and reconstruction of buildings, when the specified methods of strengthening are insufficient; if it is necessary to preserve the architectural appearance of the building.

The pillars and piers to be re-laid are dismantled after installing temporary fastenings for the duration of the work, which must be designed to absorb the loads acting on the pillar or pier being replaced. It is recommended to replace the walls one at a time.

Temporary fastenings of pillars and piers are recommended to be made in the form of wooden or metal racks on wedges, installed in close proximity to the structure being dismantled (Fig. 4.7), or by partially or completely temporarily filling openings on both sides of the pier.

Rice. 4.7 Strengthening damaged walls with racks and unloading them from the weight of the floors: 1 - lining; 2 - stand; 3 - wedges; 4 - lying down; 5 - jumper; 6 - beam

When dismantling piers and pillars, safety measures should be observed while constantly monitoring the condition of the racks and their sub-blades. It is not recommended to use pneumatic hammers to dismantle masonry of damaged walls.

For laying new pillars and partitions, materials of increased strength are used: stone materials (brick, concrete and natural stones) of grade 100 and higher on cement mortar of grade 100-150. If necessary, the masonry is reinforced with steel mesh placed in horizontal joints.

To ensure a tight fit of the new masonry to the old one, the top of the new masonry is not brought closer to the old one by 3-5 cm, followed by carefully caulking the gap with dense (“dry”) cement mortar of grade 100-150. Temporary fastenings are dismantled when the new masonry solution reaches 50% of its design strength.

The surface layers and wall cladding are restored as follows. Weathered, defrosted and peeled layers of masonry or wall cladding are removed and replaced with new masonry (cladding), structurally connected to the old undamaged masonry. It is not allowed to erect new masonry or cladding without a constructive connection with the old one. New masonry (cladding) is made from the same or more durable and frost-resistant materials using M50-100 cement mortar. The structural connection of the new and old masonry is ensured by ligating the bonded rows (if possible) or using steel mesh and frames made of rods with a diameter of 3-4 mm or “whiskers” made of knitting or annealed wire, embedded in the horizontal seams of the new masonry every 60-90 cm along height (multiples of row height). Nets, frames and “whiskers” are attached to steel pins with a diameter of 5-8 mm (Fig. 4.8). The pins are driven or embedded with M100 cement mortar into the masonry seams to a depth of 6-12 cm. “Whiskers” can be embedded into the masonry seams with cement mortar without pins (loops).

The vertical seam between the old and new masonry (cladding) is filled with cement mortar. It is recommended to replace damaged or peeled layers of masonry and cladding sequentially in sections no longer than 5 m in accordance with the PPR and in compliance with safety measures.

Depending on the structural and architectural requirements for the solidity and facial texture of the external surfaces (facades) of the walls, it is recommended to seal cracks by injection and caulking with cement mortar, laying bricks or sealing with concrete and by lining the masonry surfaces with brick (stone).

Injection of cracks with an opening of up to 4 mm is performed by injecting cement or cement-polymer mortar under pressure. When cracks open more than 4 mm, sealing cracks with mortar can be done using a mortar pump or a pneumatic blower.

Rice. 4.8 Fastening brick cladding to old masonry with pins: 1 - old masonry; 2 - facing; 3 - steel pin or nail with a diameter of 5-8 mm; 4 - “whiskers” made of wire or reinforcing mesh (dotted line) with a diameter of 3-4 mm; 5 - cement mortar

Sealing (caulking) cracks with cement mortar is recommended for cracks opening more than 3 mm in cases where complete filling of cracks with mortar is not necessary. Caulking with M100 cement mortar is carried out to a depth of 2-4 cm on each side after clearing and washing the cracks with water.

Large cracks (fractures) with an opening of more than 5 cm are laid with bricks using M50-100 mortar with or without ligation with the main masonry, or the cracks are sealed with concrete (mortar) B3.5-7.5 on light aggregates.

Filling cracks and breaks in walls is carried out when it is necessary to preserve the facial texture of brick, stone or cladding. In this case, the wall masonry along the length of the crack is dismantled to a depth of half a brick and a width of at least one brick (stone), followed by filling the cracks with a new brick in a dressing with the old one (Fig. 4.9).

In walls and partitions with a thickness of 25 cm or less, the damaged masonry in the crack zone is dismantled and replaced throughout the entire thickness of the wall. Walls and partitions that have longitudinal delamination of the masonry (longitudinal cracks) must be tightened in the transverse direction with bolts and washers. Cracks are sealed by injecting cement or cement-polymer mortar, as described above. The diameter of the coupling bolts is at least 16 mm; the pitch of the bolts along the length and height is 60-70 cm, when the bolts are staggered - 90 cm.

Rice. 4.9 Sealing cracks with dismantling old masonry

Strengthening with prestressed steel ties and belts damaged by cracks in walls and floors of one-story and multi-story buildings (Fig. 4.10, 4.11) is carried out in order to: restore or increase the solidity, spatial rigidity of buildings and the strength and stability of walls and floors; stopping the development of wall deformations out of plane (tilts, bulging); reducing or stopping the development of cracks in walls and ceilings with uneven settlements of foundations, temperature and humidity influences and with different rigidity and load of adjacent walls.

The rods must have a tensioning device (couplings, nuts) or be strained by thermal heating using blowtorches or an autogen. The tension increase should be 30-50 kN. The tension is controlled with special devices (tensometers, strain gauges, indicators) or by tapping (when struck, the tense cord should produce a high-pitched sound). The tension is carried out simultaneously along the entire contour of the building after sealing the cracks with cement mortar under pressure. The distance between the strands is recommended to be 4-6 m, so that the wall area is no more than 20 m 2 per strand.

Rice. 4.10 Fastening walls with metal ties at the floor level: a - inside the building; b - outside the building; c - section; d - option of laying strands in a fine; 1 - cord; 2 - tension coupling; 3 - metal lining; 4 - channel No. 16-20; 5 - corner; 6 - cement mortar grade 100

Rice. 4.11 Fastening a bulging wall with metal ties: 1 - wall; 2 - cord; 3 - tension coupling; 4 - traverse from channel No. 14-16; 5 - lining

In multi-storey buildings, the ties outside and inside the premises are installed at the level of the top of the floors. In one-story industrial buildings, ties are installed along the axes of trusses or load-bearing beams in the immediate vicinity of their supports and secured to them to prevent sagging.

When strengthening stone walls from the outside with belts (Fig. 4.10), the ties are laid on the surface of the walls in grooves with a cross-section of 70x80 mm, cut into the masonry, which, after tensioning the ties, are sealed with M100-150 cement mortar.

The end stops of the strands are made in the form of metal plates 10x10-15x15 cm with a thickness of 10-12 mm or from sections of channels. The ends of the rods (strands) must be threaded with a nut.

In the absence of ligation or the formation of vertical cracks at the junction of the external and internal walls, the solidity of the masonry can be restored by installing prestressed clamps made of rods with a diameter of 20-24 mm and a length of 1.5-2 m at the level of the top of the floors (Fig. 4.12).

The clamps are anchored into the transverse walls using sections of angles or channels. The clamps are tensioned by tightening the nuts. Cracks or gaps between walls are sealed with cement mortar under pressure.

Local reinforcement of corners of buildings and individual sections of walls damaged by cracks can be performed by using double-sided lining (banding) of metal strips with a cross-section of 6x80-10x100 mm or channels No. 14-20, tightened with bolts with a diameter of 16-20 mm (Fig. 4.13).

Damaged by cracks or destroyed, ordinary or wedge lintels of openings are re-laid or reinforced with steel beams made from channels. The beams are laid in grooves cut out on both sides of the wall and tightened with bolts or clamps (Fig. 4.14). After installation, metal beams are covered with mesh and plastered with M50-100 cement mortar.

Depending on the degree of damage, reinforced concrete lintels are repaired (strengthened) or replaced with new ones. When replacing or repositioning, the lintels on which beams or floor slabs rest must be completely unloaded by placing temporary fastenings in the form of racks or frames under the supports of the beams and slabs (see Fig. 4.7). Racks and frames must be installed on wedges.

Steel ties, beams, strapping, washers, clamps exposed to atmospheric influences or located in rooms with damp and wet conditions must have anti-corrosion protection.

Rice. 4.12 Strengthening with steel ties the intersection of brick walls weakened by a crack or seam: 1 - 20 mm diameter tie; 2 - washer 75x75x8; 3 - crack injected with M100 cement mortar; 4 - corner or channel; 5 - fine lined with brick

Rice. 4.13 Strengthening the corner with metal beams 1 - metal beams No. 16-20; 2 - coupling bolts with a diameter of 16-20 mm

Rice. 4.14 Strengthening ordinary and wedge lintels 1 - masonry; 2 - channel; 3 - bolt; 4 - plaster on mesh

| Previous |

Strengthening brick walls, piers and columns

Strengthening brick walls. The main methods of strengthening brick walls include:

Sealing cracks on the front surfaces of walls;

Installation of metal belts;

Installation of unloading beams;

Relaying of individual sections of walls;

Increasing their load-bearing capacity using reinforced and reinforced concrete cages;

Ensuring spatial rigidity and stability, etc.

For small stabilizing cracks, they are sealed with a cement-sand mortar with the addition of 30% lime paste. If the walls are significantly weakened, the masonry is cemented with a cement-polymer or expanding solution.

In the case when the cracks in the wall are through, then the walls are rebuilt on both sides along the front to a depth of 1/2 brick with the obligatory arrangement of ligation in one brick every four rows of masonry, and in long and wide cracks a lock with an anchor is made from rolled profile, which is strengthened with anchor bolts (Fig. 39).

Fig.39. Sealing cracks with brick inserts

in a simple lock and with an anchor

In places where through cracks form, to stabilize them, steel plates made of strip steel 50 x 10 mm are installed on both sides of the wall and secured with bolts on both sides of the wall (Fig. 40, a). The same is done when through cracks appear in the corners of the building (Fig. 40, b) and at the intersection of external and internal walls (Fig. 40, c).

Fig.40. Ways to strengthen brick walls

a) installation of steel ties on bolts; b) in the corner of the building; c – the same at the junctions of external and internal walls: 1- double-sided metal plate made of strip steel; 2 – round steel diameter

20-24 mm; 3 – the same, with threading on both ends

If there are a significant number of cracks and when sealing them does not restore the load-bearing capacity of the wall, individual sections of the walls are rebuilt.

In case of severe destruction of brick walls to strengthen the brickwork single-sided or double-sided reinforced concrete reinforcement walls are used. When installing one-sided walls, anchors are hammered into reinforced walls or installed using mortar in drilled holes, to which reinforcing mesh with a diameter of 8-10 mm with a cell size of 150 x 150 mm is welded (Fig. 41, a).

When installing reinforced concrete walls on both sides, through holes are drilled in the reinforced wall, into which metal ties with washers are installed, to which the same reinforcing mesh is welded as when installing one-sided walls. The thickness of the reinforcement walls reaches 100-150 mm (41, b).

Fig.41. Strengthening a brick wall with one-sided (a) or double-sided (b) concrete

a) – one-sided concrete: 1 – reinforced wall; 2 – floor slabs; 3 – nabetonka;

4 – pins with a diameter of 8-10 mm; 5 – reinforcing mesh with a diameter of 6-8 mm; b) – double-sided concrete: 1 – reinforced wall; 2 – reinforced concrete reinforcement walls connected by ties to the reinforced wall; 3 – reinforcing mesh welded to tie rod washers; 4 – strands with washers passed through drilled holes in the wall; 5 – holes drilled in the wall for the passage of strands; 6 – wall surface prepared for concreting (cleaning, notching, washing)

When there are many cracks on the facades of a building, they are resorted to to ensure spatial rigidity of the load-bearing frame of buildings using the device of strapping belts. The installation of metal belts is also carried out when the walls deviate from the vertical as a result of uneven settlement (Fig. 42).

Round or square steel with a diameter of 20-40 mm is used as metal belts, which are installed under the ceiling of each floor. Some ends of the metal belts are welded to pieces of corners, which are installed at the corners of the building, and the other ends are secured in turnbuckles (turnbuckles).

In cases of ensuring spatial rigidity, the tension of metal belts begins simultaneously on all floors to avoid uneven load transfer. When it is necessary to restore the verticality of the wall, the tension of the metal belts begins from the lower floor.

The specified tension force is ensured by special torque wrenches in the tension couplings.

Fig.42. Ensuring spatial rigidity of the building skeleton

1 – strands; 2 – tension coupling; 3 – metal gasket; 4 – channel No. 16-20; 5 – corner

Strengthening the walls. Strengthening the walls can be done by:

Increasing their cross-section;

Relays;

Metal frame devices;

Reinforced concrete and plaster reinforced cages;

Installation of flexible or rigid cores.

.

.

Fig.43. Strengthening the piers of load-bearing walls:

a, b) – reinforced concrete frame; c) – a holder made of rolled metal; d) – reinforced concrete core;

e) – the same, metal; 1 – brick wall; 2 – fittings; 3 – concrete; 4 – transverse steel connection;

5 – steel corner; 6 – steel strip; 7 – reinforcement frame; 8 – steel core

Strengthening brick columns and pilasters. Brick columns and pillars are reinforced in the same way as brick walls, i.e., by installing metal, plaster or reinforced concrete frames (Fig. 44).

Fig.44. Strengthening brick columns and pillars using a device

metal frame (a), reinforced concrete (b) or reinforcement (c) cage

1 – brick column; 2 – metal frame or reinforcement fittings; 3 – cement-sand mortar or cast-in-place concrete

To increase the efficiency of the metal frame, the horizontal strips are given pre-stressing using electric heating to a temperature of 120 0 C.

According to the second method, instead of strips, metal rods are used, the ends of which are welded on one side to the vertical corners of the column frame, and the other ends, which have a threaded end, are passed into pre-welded sections of corners or pipes, after which, by screwing the nuts with a torque wrench, a horizontal tension and additional compression of the column (Fig. 45).

Fig.45. Strengthening brick columns using prestressed rods

1 – corners; 2 – head segment; 3 – transverse rod; 4 – nut; 5 - washer; 6 – plaster layer; 7 – straight wedge; 8 – reverse wedge; 9 – stiffener; 10 – support corner

Brick pilasters can be reinforced using steel or reinforced concrete frames(Fig. 46).

Rice. 46. Reinforcement of pilasters with steel (a) or reinforced concrete (b) clips

1 – steel corners; 2 – connecting strips (clamps); 3 – thrust washer 10-12 mm; 4 – bolt with a diameter of 18-22 mm; 5 – caulking with cement mortar; 6 – clamp with a diameter of 18-22 mm; 7 – reinforcing mesh; 8 – concrete; 9 – concrete crackers

The reinforced concrete frame is made of class B concrete 12.5 and higher, reinforced with vertical rods and clamps. The distance between the clamps should be no more than 150 mm.

Strengthening brick walls can improve their performance characteristics. Very often you can see cracks in the walls of a brick house, which indicates their weakness and the presence of poor load-bearing support. There are various methods of strengthening brick walls to increase their durability. The article will talk about some of them.

The basis for strengthening brick walls is their deformation, the reasons for which may be:

- Design errors. These include:

- insufficient foundation depth;

- unevenness during settlement of parts of the house;

- deformations occurring in the beam covering;

- discrepancy between the load-bearing capacity of the structure and the load on it.

- Exploitation. In this case, what may have happened:

- over-wetting of styling;

- foundation subsidence.

- Errors that occurred when laying walls.

Assessment of the degree of damage to brick walls, based on the loss of bearing capacity by elements, can be: